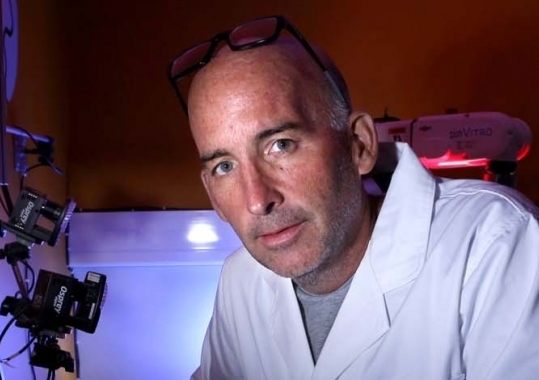

The ideas man at the interface of engineering and medicine

An exquisite example of research in action, orthopaedic researcher and surgeon Bill Walsh and his team are inventing the biomedical devices of the future.

An exquisite example of research in action, orthopaedic researcher and surgeon Bill Walsh and his team are inventing the biomedical devices of the future.

Professor Bill Walsh is a dynamo. His energy and passion are so vibrant, I swear I can see lightbulbs popping out of his head every few seconds as we talk.

I’m here in Walsh’s extraordinary Surgical and Orthopaedic Research Laboratory at the UNSW Prince of Wales Clinical School to talk about the revolutionary spinal fusion device he has developed with co-inventor Dr Matthew Pelletier; but before we get started, Walsh whisks me off on a tour of the facilities.

“I came to UNSW from Brown University in the US,” says Walsh as he shows me rooms full of gleaming 3D printers and numerous other outlandish machines that stretch, crush, magnify and analyse whatever falls under the team’s gaze.

Walsh established the lab in 1993, in a small room in the old stone Edmund Blacket Building at the Prince of Wales Hospital and over the last 23 years it’s evolved into this: an 800-square-metre space with 14 staff, and with surgical theatres a mere 50 metres away, the lab offers a perfect interface between engineering and medicine.

“I have a fairly old-school view of what a lab should be and deliberately set it up so my surgeon friends, university colleagues and industry partners can come to me and say, ‘Bill, this is the problem that we have to solve – can you help?’”

In what is surely an exquisite example of research in action, Walsh has created this amazing facility through a wide variety of projects, collaborations and partnerships; with no institutional funding. “I’ve always had really strong support from the University but in terms of raising money and buying equipment, I’ve built the lab from the ground up!”

After the tour we get down to talking about the reason for the interview: the Thru-Fuze™ device – designed to treat patients with chronic back pain and degenerative disc disease.

Inspired by a keen awareness of the shortcomings of current surgical treatments for spinal fusion, Walsh says it was actually a biological hint that triggered the exciting what if…

“In traditional spinal fusion we’ve always relied on bone graft material to bridge two bones together. The problem is that the bone has to work very hard to integrate through the graft material. One thing we noticed through the microscope is that if you perturb a bone it always gives a response – much like the bump you get when you hit your shin on something hard. Seeing this led us to think, ‘What would happen if, rather than having to grow from one bone to another, bone only has to grow into two sides of a bridge-like device?’”

They rolled up their sleeves and got to work. They quickly proved the idea in concept and, filing the IP through UNSW Innovations (UNSW’s commercialisation company), immediately attracted the attention of Intellectual Ventures and funding to the tune of $2.3 million to develop the technology.

Now, two and a half years after the initial idea popped, Walsh and Pelletier have received almost $1.6 million in additional funding from the NSW Department of Health’s Medical Devices Fund to take the device on the pathway towards commercial use with their first in-man trial. “We have a spine surgeon who’s collaborating with us and hope to undertake surgery on patients in the next couple of months,” says Walsh.

The Thru-Fuze device targets chronic back pain, the most common reason for pain and disability in people aged under 50. (Photo: UNSW TV)

With success looking likely, this device has the potential to reduce the cost of surgery and improve the reliability of spinal fusion. With current surgical treatment the bone must grow and form its own bridge which can take up to 12-18 months or longer to complete; whereas with the Thru-Fuze™ device, it’s successful at six weeks from a biomechanical perspective, and gets better with time.

“This proves that nature is the ultimate engineer and bone is the most elegant engineering base material. If we could copy bone, we’d be getting somewhere! Ultimately,” continues Walsh, “we want to make a device that is efficacious and economical for the healthcare system; and our primary goal is to improve patient outcomes.”

This article was first published on the UNSW Engineering website.