UNSW researchers awarded for innovative marine propeller blade

'Intelligent' shape-shifting propeller blade monitors its own performance and adapts to changing conditions in the water.

'Intelligent' shape-shifting propeller blade monitors its own performance and adapts to changing conditions in the water.

Researchers at UNSW Sydney have taken out a JEC Asia Innovation Award for their research, testing and production of a “shape adaptive marine propeller” that promises more efficient and longer-lasting propellers for marine applications.

UNSW Engineering Professor Gangadhara Prusty accepted the marine category award at a ceremony in Seoul last week, on behalf of the Australian Research Council (ARC) Training Centre for Automated Manufacture of Advanced Composites (AMAC) and program partners the Australian Defence Science and Technology Group (DST).

Professor Prusty is the Director of AMAC, based at UNSW’s Kensington campus. He said: “We’ve designed an intelligent propeller blade that can operate efficiently under changing conditions in the water. It’s made of very lightweight composites that are strong, but flex and twist to change shape to achieve maximum propulsion efficiency.”

Marine propellers are typically made with a nickel-aluminium-bronze (NAB) compound metal, which is prone to erosion, and by comparison with carbon fibre is much heavier, inflexible and expensive. Reduced noise generation and the absence of a detectable “magnetic signature” from a composite propeller is also a desirable characteristic, especially for defence applications.

A step change in composite technology for marine vessels

The manufacturing process of the winning propeller blade was also integral to UNSW’s success at the awards, with its unique digital production and sensor technology.

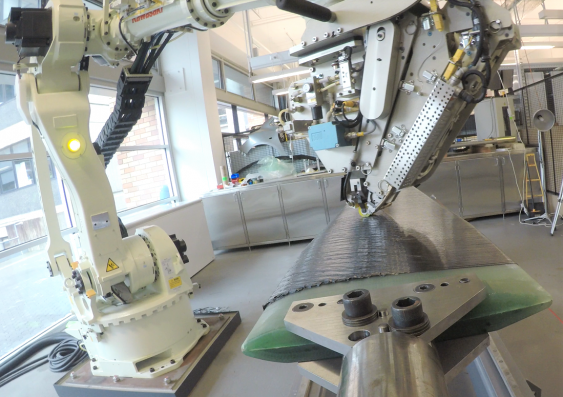

The research team manufactured the propeller blade using Automated Fibre Placement (AFP) technology, where prototypes are based on a “digital design” that can be optimised throughout the process and manufactured at an unprecedented rate, also minimising waste.

The process also embeds fibre-optic sensors into the blade that provides strain measurements, useful for prototyping and manufacturing, as well as performance and maintenance across its entire life cycle.

Kerryn Caulfield, CEO of Composites Australia Inc., the peak industry body for the Australian composites sector, said: “This shape adaptive advanced composite technology for marine vessels is an important step change for our nation.”

Professor Prusty said he was honoured to receive the award on behalf of UNSW, AMAC and DST.

“I am very proud that we have produced this significant breakthrough in demonstrating sensor-embedded, automated manufacture of adaptive structures using advanced composites.

“There are many opportunities for applying our technologies across the aerospace, civil, defence and automotive sectors, and I am looking forward to expanding our research for the next generation propeller blade using digital technology to large scale manufacturing solutions.”