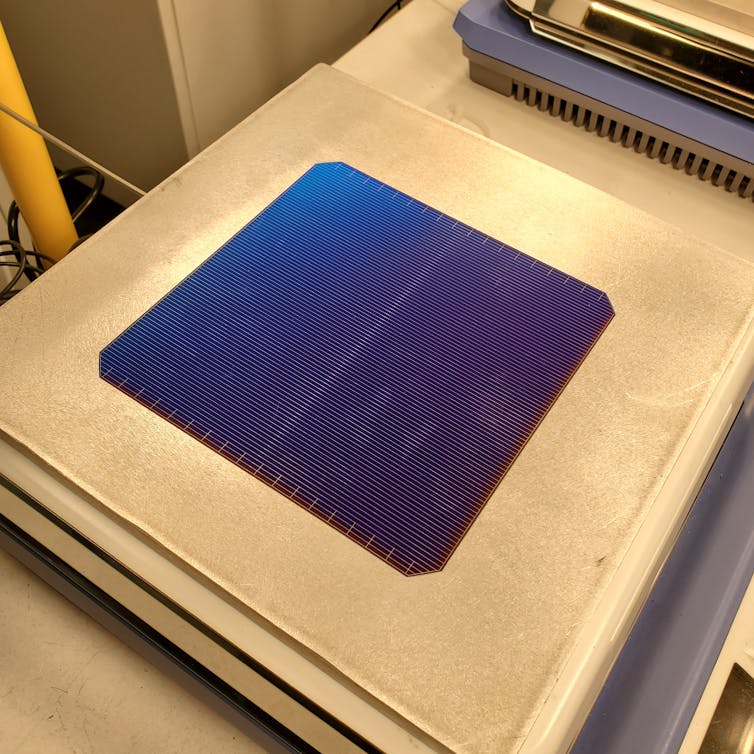

The sunlight that powers solar panels also damages them. ‘Gallium doping’ is providing a solution

The process of manufacturing gallium-doped solar panels was under a patent until last year. It's only now that this method has started to pick up steam.