Carbon copy: new method of recycling carbon fibre shows huge potential

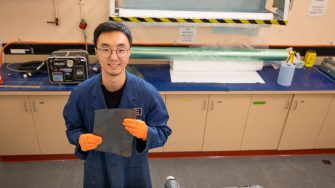

Ultra-light cars made from recycled carbon fibre are a step closer thanks to a new method of recycling, developed at UNSW Canberra, which leaves the product substantially stronger.