How agri-waste is becoming low-carbon materials

Converting or managing traditional waste streams is leading to brand-new products.

Converting or managing traditional waste streams is leading to brand-new products.

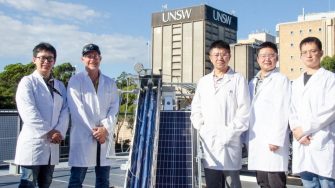

UNSW Associate Professor Jason Scott is pioneering circular economy technologies for sustainable energy and waste management, with a focus on converting waste streams into new products. This is coming to life across a number of projects, including one which combines waste from salt mining with carbon dioxide to create low-carbon building materials.

Collaborating with Australian chemical company EcoMag Ltd, A/Prof. Scott and his team recycle industrial agri-waste into eco-friendly plasterboard, aiming to reduce the construction sector's carbon footprint. Over four years, they transformed magnesium from solar salt bitterns, agri-waste (straw and wood), and carbon dioxide into low-carbon plasterboard and cladding.

"EcoMag developed the process to produce kilogram volumes of its hydrated magnesium product, but saw UNSW as a resource to help develop new products, technologies, and ideas,” says A/Prof. Scott. "We’re working with them to find more applications for their products and make their process more sustainable.”

The process integrates carbon dioxide capture and utilization. "Their process requires a carbonate, and we use CO2 to form that carbonate and the final product," A/Prof. Scott explains. "If we have a CO2 emitter, we capture that CO2, lock it in the carbonates in the product, and form it into drywall or cladding."

This innovation has enabled the team to assess EcoMag’s magnesium product as an alternative to current plasterboard. It’s also allowed them to consider whether this material has comparable properties to what’s currently on the market, including flame resistance, tolerance to moisture, strength and flexibility.

Funded by the Future Food Systems CRC, the project involves close collaboration with EcoMag’s team, particularly Chief Technology Officer Dr. Tam Tran. "The team has established a process to capture and store CO2, with the produced hydrated magnesium carbonate also acting as a fire retardant,” A/Prof. Scott says.

With demand for circular economy construction materials growing, this innovation holds significant commercial potential. “This idea has real-world, commercial potential,” A/Prof. Scott adds.

Beyond carbon capture, A/Prof. Scott is also engaged in renewable hydrogen generation with Rio Tinto. This project focuses on sustainable hydrogen production and managing organic waste from remote communities. A collaboration with Rio Tinto began in 2022 to advance UNSW’s prototypes towards commercialization.

“We spent nearly four years developing a prototype system to convert sugar waste and sunlight into clean water and hydrogen,” A/Prof. Scott explains. “We could take 25 litres of wastewater, concentrate the sugar, produce about 20 litres of clean water, and generate about 100 litres of hydrogen in a day.” Rio Tinto is interested in using this technology to repurpose food waste into energy.

With growing potential and demand for his work, A/Prof. Scott hopes to see his research have a meaningful impact. “I’d like the impact of this work to find some use in the community,” he explains. “It might be a step towards something better for the future.”

As Australia’s best engineering faculty turns 75, there are just as many reasons why we’ve earned that title. Discover new stories weekly, celebrating the successes that have enabled progress for all.