Local manufacturers explore the industry's evolution at UNSW event

The potential of emerging technologies was keenly discussed at a UNSW summit exploring the reinvention of Australian manufacturing.

The potential of emerging technologies was keenly discussed at a UNSW summit exploring the reinvention of Australian manufacturing.

New technology offers a major opportunity for the Australian manufacturing industry to transform into an innovative and collaborative network, producing high value, sustainable materials that can deliver real economic benefits, said the head of the Advanced Manufacturing Growth Centre (AMGC) at UNSW Sydney on Wednesday.

Industry leaders from CSIRO, NSW Environmental Protection Authority (EPA), Innovative Manufacturing CRC, UNSW Science, Engineering and others met for the AMGC’s Path to Advanced Manufacturing event that featured researchers and manufacturers leading discussions on emerging manufacturing trends and the future of an industry undergoing fundamental change.

“One-in-10 Australians are employed in manufacturing and this number will continue to grow,” said Michael Sharpe, NSW Director of AMGC. “Collaboration is now essential for manufacturing. We are breaking down barriers by getting industry and researchers working together and producing new materials and processes. We are evolving from an industry stuck in our own factories to breaking down barriers and working together.”

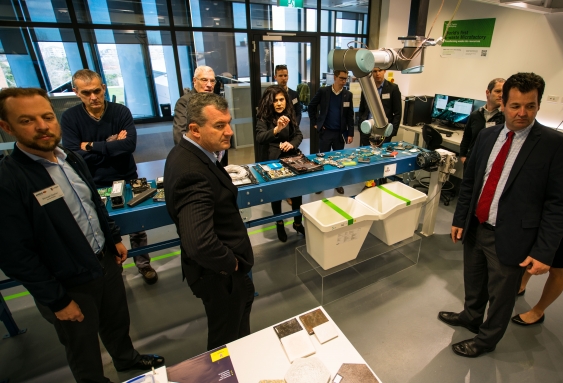

Professor Veena Sahajwalla and manufacturing industry leaders at UNSW's e-waste microfactory. Photo: Luke Gresham

The expanding links between academics and local manufacturers was highlighted by Professor Veena Sahajwalla, Director of UNSW’s Centre for Sustainable Materials Research and Technology (SMaRT) Centre, in her presentation and on a tour of the SMaRT Centre ‘microfactories’, a range of machines and devices that use patented technology to turn discarded products and containers into new, high-value and reusable materials.

“The SMaRT Centre partnership with AMGC has allowed UNSW to work with businesses including e-waste recycler TES and mining manufacturer Moly-cop, and realise that manufacturing is entering a new phase where big and small business work together. Large corporate steel manufacturers are looking five years ahead, they want to use innovation in combination with long-existing technology.”

Professor Sahajwalla emphasised that the new recycling and reforming process can be transported and relocated easily, or relocated to where a stockpile or suitable site exists or work in combination with “mega-factories”.

“Microfactories deliver critical materials so they not only regenerate materials out of plastic, glass and other waste but incorporate it as part of the process. New technology can produce high performance materials, such as ceramics, out of waste resources, and shows us the possibilities for manufacturers to create completely new surfaces.”

New materials, critical parts and components can then be exported to the rest of the world, contributing to an ecosystem that supports the economy and is part of the global supply chain.

“Growing and creating new products enables business of all sizes to develop innovative solutions building on the back of existing practice. We’ve had a tremendous number of opportunities through networks to have the conversations and exchange of ideas. It starts at a grass roots level,” said Professor Sahajwalla.

Professor Veena Sahajwalla and manufacturing industry leaders at UNSW's e-waste microfactory. Photo: Luke Gresham

In the afternoon session, Alan Wigg, Project Officer at NSW EPA, addressed the implications of China's 'National Sword' policy and the country’s restrictions on imports of recycled materials and manufacturing.

“There is difficulty finding end markets for recyclable material, and limited local reprocessing. The fundamental problem that needs to be addressed is the state’s dependence on exporting recyclable materials,” said Mr Wigg.

“A global shift towards circular economy is occurring, and National Sword presents a unique opportunity for NSW to develop local end markets for recycled products and stimulate industry investment.”

Mr Wigg said a new government grant, the Product Improvement Program, would target the local manufacturing sector as well as waste recycling facilities. The program will allocate $4.5 million for projects that reduce the amount of unrecyclable material left at the end of the recycling process, with grants supporting up to 50% of the capital costs for equipment or infrastructure.

“One of the main changes to previous programs is including the manufacturing sector,” said Mr Wigg. “A major program objective is to increase the use of recovered plastics, glass, and mixed paper/cardboard in the manufacture of products within NSW.

“We are encouraging collaboration between suppliers of recycled material and potential users of that material.”

In an opening address to industry, UNSW's Deputy Vice Chancellor (Enterprise), Professor Brian Boyle, said: “In 2016, UNSW committed to doubling our engagement with industry in the next five years, to ensure our research has an impact in the society in serves. We are on track with an annualised growth of 20% in our engagement with industry.

“The Division of Enterprise was established to support academics working with business partners and a way for those business partners to access high-quality research. Our partnership with AMGC is central to the growth of engagement and to openly address the challenges for business and industry.”