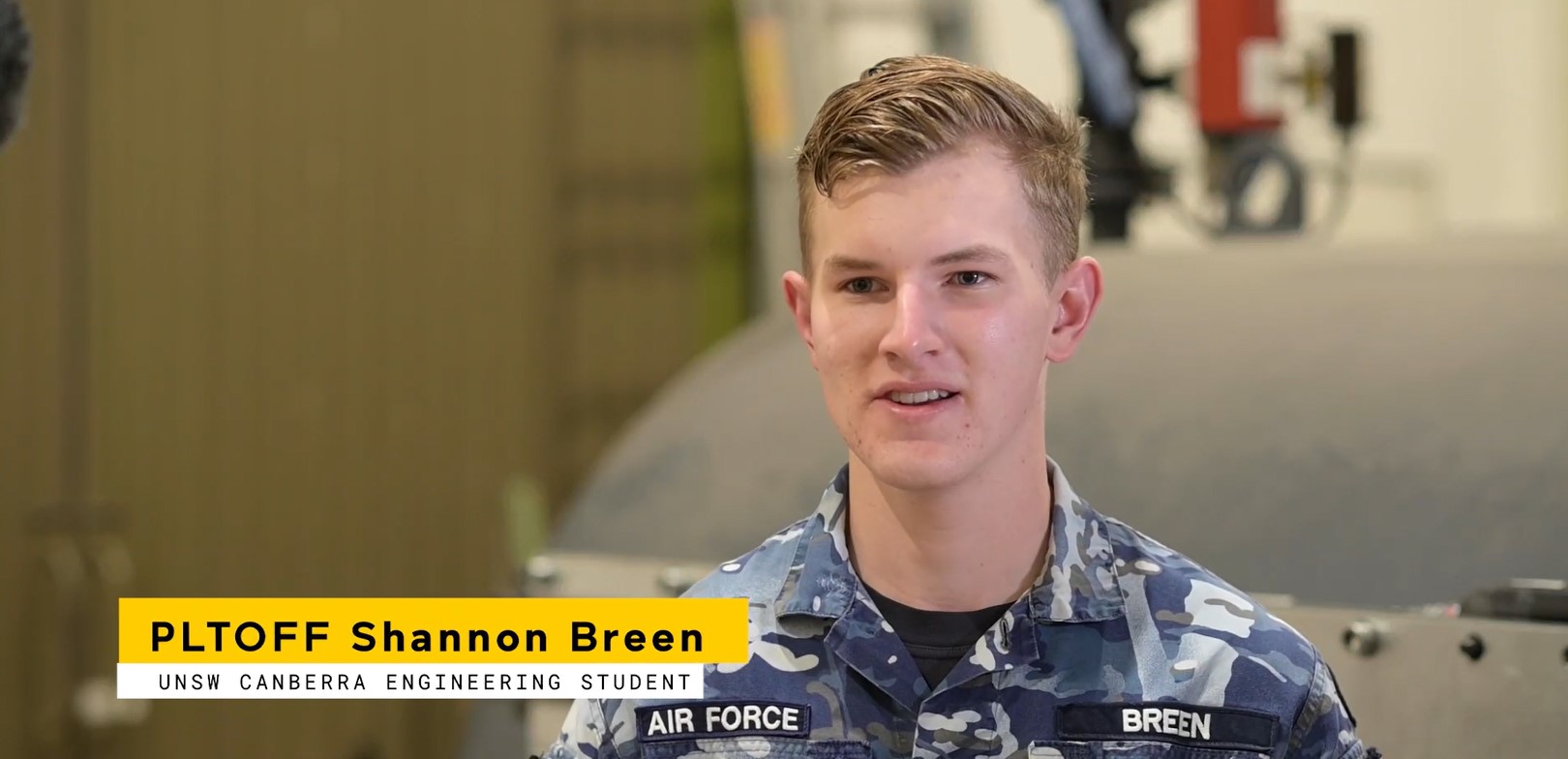

My thesis: Pilot Officer Shannon Breen

UNSW Canberra student Shannon Breen has used his fourth-year thesis to investigate how a polymer/spray adhesive coating could be used to improve plain weave ultra-high molecular weight polyethylene

UNSW Canberra student Shannon Breen has used his fourth-year thesis to investigate how a polymer/spray adhesive coating could be used to improve plain weave ultra-high molecular weight polyethylene

UNSW Canberra student Shannon Breen has used his fourth-year thesis to investigate how a polymer/spray adhesive coating could be used to improve plain weave ultra-high molecular weight polyethylene (UHMWPE) for potential use in body armour.

The Pilot Officer and aeronautical engineering student used the University's gas gun to test how a variety of fabric samples would respond to ballistic impact.

"My thesis involved coating ultra-high molecular weight polyethylene fabric in order to improve their surface energy and the ballistic characteristics of the fabric,” Shannon said.

Picking up from the work previously done by his supervisors Dr Damith Mohotti and Dr Hongxu Wang, Shannon coated plain weave fabric with various spray adhesives.

"That hasn't really been applied before with spray-coated polymers, so that was a new field that we explored and looked to improve – there was a fair gap in the literature,” Shannon said.

Shannon began with a prerequisite test called 'single yarn pullout testing', which evaluated the properties and characteristics of the fabric. This was then followed by ballistic testing using the gas gun.

Three fabric samples were tested at five different velocities.

"The main discovery we found was the rubber-coated polymers – the spray coatings that were used – were the best performing in both the yarn pull out testing and the ballistic testing,” Shannon said.

"So, one of the main assumptions we made before the yarn pullout testing was that the results obtained there would correlate directly with the ballistic testing. That assumption was correct, and that really helped the project move forward, we could test the best performing yarn pullout samples in ballistic application."

Plain weave UHMWPE fabric is generally not used in body armour due to its low-surface energy. However, the ultra-high molecular polyethylene coating provided good protection from ballistics.

"This fabric is found in both hybrid armours and soft armors, so it can be used in any sort of field where that's required,” Shannon said.

He said this fabric complies with the National Institute of Justice (NIJ) protection levels IIA and IIIA, which means it can be used for bulletproof vests.

“UHMWPE in a unidirectional construct is often used in armour components (such as vests) that meet the NIJ standards of IIA and IIIA,” Shannon said.

“An extension of my thesis work was investigating the applicability of my plain weave coated samples in meeting those NIJ standards. While plausible, it is not practical.”