Facilities

Our world-class facilities in PNPT support our research efforts on precision fabrication and nanotechnology.

-

The Buehler Isomet 5000 is a linear saw that includes the SMARTCUT system to automatically adjust the feed rate to provide consistent, quality cuts and to prevent specimen and machine damage. Its precision specimen positioning system allows for precise applications and enables the cutting of delicate specimens without minimal deformation.

-

The tribometer is a multi-functional platform with nano and micro capabilities able to perform varying tasks: Pin-on-disk at room and elevated temperatures (up to 1,000 oC), linear scratch with or without ramping and indentation.

-

The Analytical Centre and its Electron Microscopy Unit at the UNSW provide a comprehensive set of analytical and electron microscopy facilities for our research in the microanalysis of materials. These include AFM, SEM, TEM, FIB, XRM, EPMA and XRD.

-

The HAFCO Metalmaster is a manual centre lathe, with 166mm centre height, and 750mm distance between two centres.

-

This apparatus is used to study the dynamic behaviour of a material over a wide range of strain rate (up to 105 1/s) and temperature (up to 1,000 oC).

-

The Hysitron TI 950 Triboindenter is a nanomechanical testing instrument of high sensitivity. Its control module can provide the precision of feedback-controlled nanomechanical testing with excellent noise floor performance.

-

This high temperature RFDA HT 1050 unit is a furnace specially designed to perform impulse excitation measurements up to 1050 oC. It is equipped with a resonant frequency and damping analyser (RFDA) for a non-destructive determination of the Young’s modulus and Poisson’s ratio of a material at a given temperature within the capacity of the fanace.

-

The Logitech PM5 is a single workstation lapping and/or polishing machine, designed for small scale polishing of thin wafers.

-

The HAFCO Metalmaster 301 is a conventional milling machine, whose work spindle can be shifted between vertical and horizontal positions, and the spindle travel distance is 120mm.

-

This is a multi-function machine with 9 programmable axes capable of turning, milling, drilling, tapping, threading, and grinding. Machining forces can be measured in situ.

-

This machine is a 5-axis turning lathe with air bearing spindles. Its PC-based CNC motion controller has a Windows operating system and 0.01 nanometre programming resolution. The machine has the option to use a rotary B Axis, C Axis positioning control, Fast Tool Servo system, grinding and micro-milling attachment and workpiece error Compensation system to machine aspheric, toroidal surfaces, freeform, linear diffractive, and prismatic optical structures. The milling spindle has a rotational speed of 60,000 rpm.

-

This is an X-ray diffraction machine for the non-destructive measurement of residual stress in components/structures made of polycrystalline materials such as metals and ceramics. The specimen size can be as small as a few millimetres but can also be in a few metres.

-

This machine can be used for roll forming of sheets and wire. It has the in-situ measurement capacity of rolling force and torque.

-

This device can be used for high-precision dynamic balance of machine tools, spindles, high-speed spindle motors, high-speed slicers, dicing saws, centrifugal machines and grinding wheels of grinding machines. The balance measurement corrects balancing at a fixed speed up to 61.000min-1 with a resolution of ±0.001μm.

-

The semi Micor Analytical GH 252 is an analytical balance allowing weighing at the highest resolution of 0.01mg. The balance can incorporate automatic self-calibration when it detects ambient temperature changes.

-

This CNC cylindrical grinder provides simultaneous 2-axis control with a plain wheel head traverse type. The maximum grinding length is 250mm, and the maximum grinding diameter is 100mm.

-

This apparatus is for automatic, micro-processor controlled electrolytical polishing and etching of metallographic specimens. It contains a scanning function for easy determinations of parameters, with a database of methods for various materials, short polishing times and maximum reproducibility.

-

The Tegra is a grinding and polishing system for the preparation of materialographic samples. The disk diameter is 200mm.

-

The Zeeko IRP 200 is a 7-axis CNC optical polishing machine capable of producing ultra-precise surfaces on a variety of optical materials and surface forms. The machine axes can be used for traditional spiral polishing or raster polishing within a total envelope size of 300x260x130. The polishing can be for parts up to 200mm in diameter or freeform parts up to 200mm x 200mm.

-

This is a generally-purposed, three-dimensional surface structure analyser, which provides graphic images and high resolution numerical analysis to accurately characterise the surface structure of test parts. It uses interferometry to image and measure the microstructure and topography of three dimensions.

-

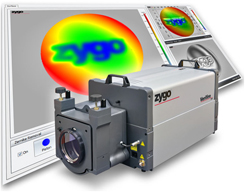

This interferometer system provides high-accuracy measurements of flat or spherical surfaces, and transmitted wavefront measurement of optical components and assemblies. It uses the precision mechanical phase modulation to show fine measurement detail on parts with accuracy and repeatability. The equipment can be used to measure optical components like flats, lenses, and prisms - precision metal components like computer disks, bearing and sealing surfaces - polished ceramics, and contact lens moulds.

-

The Buehler SimpliMet 2 is a specimen mounting tool, which has a hydraulic system providing positive compression to produce a range of sample sizes.

-

The Toshiba GMP-211 has the capacity to replicate high precision optical components from glass without grinding and polishing. The process is also known as ultra-precision glass pressing. It's used to manufacture precision glass lenses for consumer products such as digital cameras, and high-end products like medical systems.