Archived

Gas separation membrane processes offer unique benefits over amine solvent absorption for CO2separation and capture from power plants with smaller footprints and reduced chemical usage. However, current commercial membranes cannot provide the required high CO2 permeation rates or selectivity (CO2/N2 selectivity) to deal with the large volumes of either syngas for pre-combustion or flue gas for post-combustion capture. Development of high performance integrally skinned asymmetric membranes promises to be one of the most cost- effective choices due to the low fabrication cost, high membrane module packing density and low operating pressure drop. Recent studies using rubbery polymer and blending with other block-copolymer have reported significant improvements in CO2 permeability and CO2/N2 selectivity.

The current study focuses on using commodity polymeric materials blended with selected high CO2 permeation polymer components for fabrication of flat sheet and hollow fiber membranes. The flat sheet asymmetric blended membranes made from the poly (2, 6-dimethyl-1, 4-phenylene oxide) (PPO) polymer and a poly(ethylene oxide) (PEO) and poly(dimethyl siloxane) (PDMS) based additive, were casted and gas separation performance was compared with membranes with virgin polymers. Addition of 2 to 5% PEO/PDMS additive have resulted in membranes with higher CO2 permeability by factor of 3 compared to the non-additive membrane while CO2/N2 selectivity was also increased by a factor of 2. Preliminary tests with hollow fibers fabricated with Matrimid blended with 1% to 8% PEO and PDMS block-copolymer additive have achieved twice the CO2 permeance and three times the CO2/N2 selectivity compared to the fibers made with pure Matrimid.

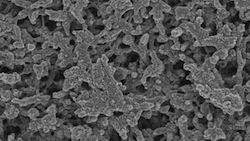

Characterization of those in-house fabricated membranes with and without additives using Scanning electron microscopy (SEM), energy dispersion of X-ray linear scanning (EDX) and X-ray photoelectron spectroscopy (XPS) techniques provided insight of mechanisms of membrane performance improvements caused by the additives and potential further improvements.

Archived

Greenhouse Gas Technology

CO2CRC