Engineering ceramics are based primarily on pure oxides, carbides, or nitrides. Of these the most important compounds are alumina, Al2O3, silicon carbide, SiC, silicon nitride, Si3N4, and zirconia, ZrO2.

Alumina is made from a hydrated aluminium oxide known as bauxite, Al(OH)3. The bauxite is crushed and purified and then heated to 1150°C to decompose it to alumina. The most common example of alumina in modern times is in its use as an insulating material for spark plugs.

Silicon carbide and silicon nitride are made by reacting silicon with carbon and nitrogen respectively. They are hard, refractory materials with very high resistance to oxidation at elevated temperatures. SiC is commonly used as an abrasive and as a reinforcement in metal matrix composite materials. Si3N4 is being developed as a high strength coating material and for use in advanced engines.

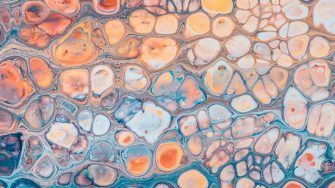

Zirconia is made from either the natural hydrated mineral or from zircon, ZrSiO4. A high fracture toughness partially stabilised zirconia (PSZ) can be produced by combining with 9% MgO and using special heat treatments.