A common type of corrosion is known as galvanic corrosion.

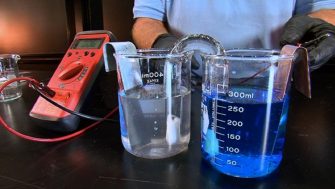

Galvanic corrosion occurs when two different metals are connected in an electrolyte and one metal corrodes in protection of the other.

One metal is corroding in the same manner as we saw in wet corrosion (M —» Mn++ ne-) while the other metal is reacting (Mn++ ne- —» M).

From these two reactions we can see that the anodic electrode corrodes and the cathodic electrode is protected. The corroded metal is called the sacrificial anode.

Galvanic corrosion can cause unwanted accelerated corrosion when it is not considered during design or construction, however it can also be used to advantage.

When considering which metal will corrode we can look at the galvanic series. Metals closer to one another generally do not have a strong effect on each other, but the further apart two metals are, the stronger the corroding effect on the one higher in the list.

Anodes and cathodes arise in many ways. As well as connection between two different metals, a plain metal surface can have anodic and cathodic areas. For example:

- Grain boundaries can be anodic with respect to grain interiors.

- Cold worked regions are anodic to regions not cold worked.