Lightweight fuel storage is a critical technology for low-cost access to space, which is recognised by the Australian Government as a national priority. Although lightweight and strong fibre-reinforced polymer composites have already been deployed in space vehicles, storage of cryogenic propellants (such as liquid hydrogen and liquid oxygen) still relies on metallic tanks. Recent efforts to use carbon fibre-reinforced polymer composites to lighten fuel storage vessels have been unsuccessful because of the matrix-cracking problem caused by the high thermal residual stresses between plies of different fibre orientations coupled with the low fracture resistance of the matrix material at cryogenic temperatures. The matrix cracks can link up to form interconnected escape channels for gas as well as degrade the structural safety of the vessels.

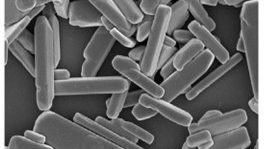

Funded by the ARC Discovery Project (DP190102790), this project aims to develop novel composite materials technologies for cryogenic space applications. Our team consists of Professor Chun Wang, Dr. Shuying Wu, Professors Tony Kinloch and Francis Rose, supported by Dr. Saiful Islam and Mr Wenkai Chang. By focusing on searching nanomaterials with negative thermal expansion that can serve the dual functions of reducing thermal residual stress and increasing the resistance to fracture, we have discovered that cupric oxide (CuO) nanorods can fulfill these purposes: they display a close-to-zero coefficient of thermal expansion at cryogenic temperatures, due to the magnetostriction effect, and they initiate void growth resulting in significant toughening of the epoxy matrix even at cryogenic temperatures, which has not been reported before. Coupled with other key characteristics such as low thermal expansion, large surface area due to nano-size, and an elongated shape that promotes pull-out toughening mechanisms, CuO nanorods have been found to increase the fracture energy of the epoxy by 260% at −196◦C. This remarkable increase in the fracture energy at cryogenic temperatures greatly improves its resistance to matrix cracking, making it more promising to be used for manufacturing tanks for storing cryogenic propellants.

Toughening mechanisms of CuO nanorods at cryogenic temperatures

Plenary and keynote presentations

- 10th Australasian Congress on Applied Mechanics, 29 November - 1 December 2021

- 12th International Conference on Structural Integrity and Failure, 5-8 December 2021

Publications

- Chang, W., L.R.F. Rose, M.S. Islam, S. Wu, S. Peng, F. Huang, A.J. Kinloch, and C.H. Wang, in Composites Science and Technology, 2021. 208: p. 108762.

- Chang, W., F. Rose, S. Wu, A. Kinloch, and C. Wang. Through-thickness crack growth resistance in fibre composites and its role preventing ply cracking in cross-ply laminates. Engrxiv.Org 2022